Stair Parts /

News & Blog

Stair Parts /

What is Powder Coat? How it Works and Why You Need It

News & Blog

Even if you’ve never heard of powder coat, you’ve probably seen it before. You may have assumed products like bicycles, cars, railings, furniture, and more are just painted with a special, thick paint.

But don’t be fooled – powder coat is very different than paint. Powder coat, like it sounds, is actually made of a fine, powdery dust. Through a special process, the powder covers metal products to create a layer even more durable than paint, improving corrosion resistance and providing a long-lasting, beautiful finish.

Getting a great powder coat finish is hard work and labor intensive. Care must be given to every detail to achieve a perfect result. When manufacturing our Viewrail products, we know that it’s essential for your posts and railing to resist corrosion and stay looking beautiful for years. That’s why we’ve refined the process to achieve the most professional results in the industry.

Overview of the Viewrail Powder Coating Process

There are three stages in our powder coating process: preparing the metal, applying the powder coat, and baking to form a strong seal. While all steps are important, we’ve found that a flawless finish depends on the careful execution of preparing and cleaning.

Viewrail posts, handrails, and other powder coated parts are prepped in a machine called a Wheelabrator, which is much like a sand blaster – but more powerful. This process etches away imperfections and smooths out sharp corners. It also creates a rough surface that’s perfect for the powder coat to attach to, which is crucial for the perfect finish.

Next, we put the parts through a 5 stage dip process. The first tank is a heated and treated acid wash, which helps remove any oil, dust, or mechanical debris from the post. Tanks two and three are both Reverse Osmosis water tanks that remove any liquid from tank one with neutral water. Tank four is a Zirconium rinse, which is a treatment that vastly improves corrosion and rust resistance. Tank five is a final rinse in RO water for a clean finish.

The post is then hung up and run through the drying oven. This oven not only dries the post but heats up the metal and then cools it, which allows “outgassing”. Every object has some sort of air, or gas, in between the molecules which make it a material. By heating up the metal, the material expands, and by cooling it down the material contracts. The combination of these two processes helps expel any gas. Viewrail chooses to do this at this stage in the process before the powder coat is applied in order to avoid the expelled gas poking holes in the surface

of the powder coat finish.

After the post is heat dried and then cooled, it is moved through the powder coat room. This room constantly holds the temperature and humidity level at which the powder coat is most successfully applied. The post is given an electrostatic charge and moved through the powder coat booth, and due to the charge of the post, the powder locks onto the post for full coverage. Finally, the post is then moved into a large oven where the powder coat is “baked” onto the post. Each step is meticulously executed to bring the best finished product to the customer.

Why You Might NEED Powder Coating

There are several perks to using powder coated posts for your Viewrail project. Functionally, it helps protect posts from the elements. This means more time enjoying your view and less time maintaining your posts. Especially for aluminum posts and railing, which are more susceptible to corrosion, powder coat helps keep your system looking beautiful for longer.

Why You Might WANT Powder Coating

Besides powder coating’s functional benefits, it also looks beautiful. It provides a clean finish that is consistent in texture and color, taking the professional construction of Viewrail posts and handrails to the next level of smooth, simple elegance.

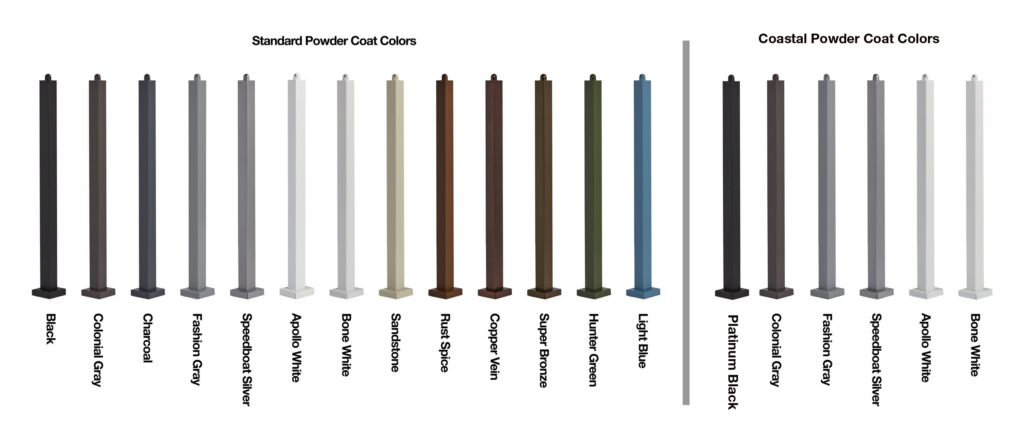

Powder coat also provides additional design options. Choose from over 15 different shades to coordinate with your home decor. Our most popular powder coat color is Black, but many of our customers also love Apollo White, Copper Vein, and Charcoal. We suggest that you order a sample of the finishes you’re interested in so you can compare it with the other aspects of your home design.

Our team takes the time to do powder coating the right way. As detailed above, we have refined the process for powder coating on our railing systems, producing the highest quality finish in the industry. We are proud to provide a beautiful and strong product – we can’t wait to see how you’ll use it to transform your space!